➲ You might be expert in cad tool and build the most beautiful cad geometry, but if it is not manufacturable, then it’s not qualified to be a design.

➲ Design for Manufacturing (DFM) is very crucial and non negotiable aspect of design.

➲ And that’s why, knowledge of manufacturing processes is mandatory skills for mechanical design engineers in order to design any product.

___________________________________________________

⏩ Author – KEVIN KUTTO

___________________________________________________

What are different Manufacturing Domains?

➲ Design is the process to transform customer’s needs into tangible & functionally working product or features which will solve the customer pain areas (problems), reduce work efforts or improve work efficiency.

➲ The final outcome of any functional design is the working Product which is ready to be used by customers.

➲ Product is made up of many parts assembled together, ranging from few to even thousands of them.

➲ Parts in the assembly could be combination of plastic, stamped, forged, casted, machined, 3D Printed ones.

➲ The greater challenge in front of design engineers is to design each of these parts in such a way that they will be readily manufacturable in mass production, without big problems in the working of manufacturing tool, without creating surface defects and deliver it with minimum cost.

➲ Every material & manufacturing process offer variation in tolerances and finish which might affect tolerance stackup and eventually, a function.

➲ Every manufacturing process is unique in terms of materials, tools, possible surface defects and manufacturing challenges as well as cost.

➲ The part geometry & material selection could greatly influence manufacturability, surface quality and cost of the produced parts. And, that’s the reason why, manufacturing process knowledge in term of design considerations, material selection, tooling considerations and surface defect mitigation could reduce the possibility of manufacturing defective parts up to the great extent.

➲ According to the uniqueness of the processes and materials, manufacturing could be broadly grouped into multiple manufacturing domains to facilitate systematic study.

___________________________________________________

The most popular Manufacturing domains are:

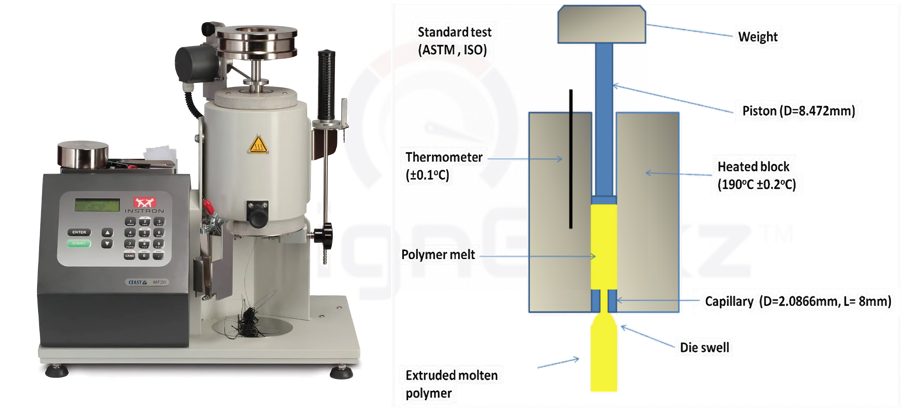

➲ Plastic Design

➲ Sheet Metal Design

➲ Forging Design

➲ Casting Design

➲ Machining & Welding

➲ 3D Printing

___________________________________________________

➲ Plastic & sheet metal domains are most popular in automotive, home appliances & aerospace industry which makes sense as most of the parts in these industries are made up with these two processes.

➲ The weight to strength & cost ratio is very good for plastic & sheet metal, that’s why these processes are very popular.

➲ In my opinion, we as a design engineers need to have in depth knowledge of all manufacturing domains, but Plastic & sheet metal domains could be a great start in that long-term journey of learning.

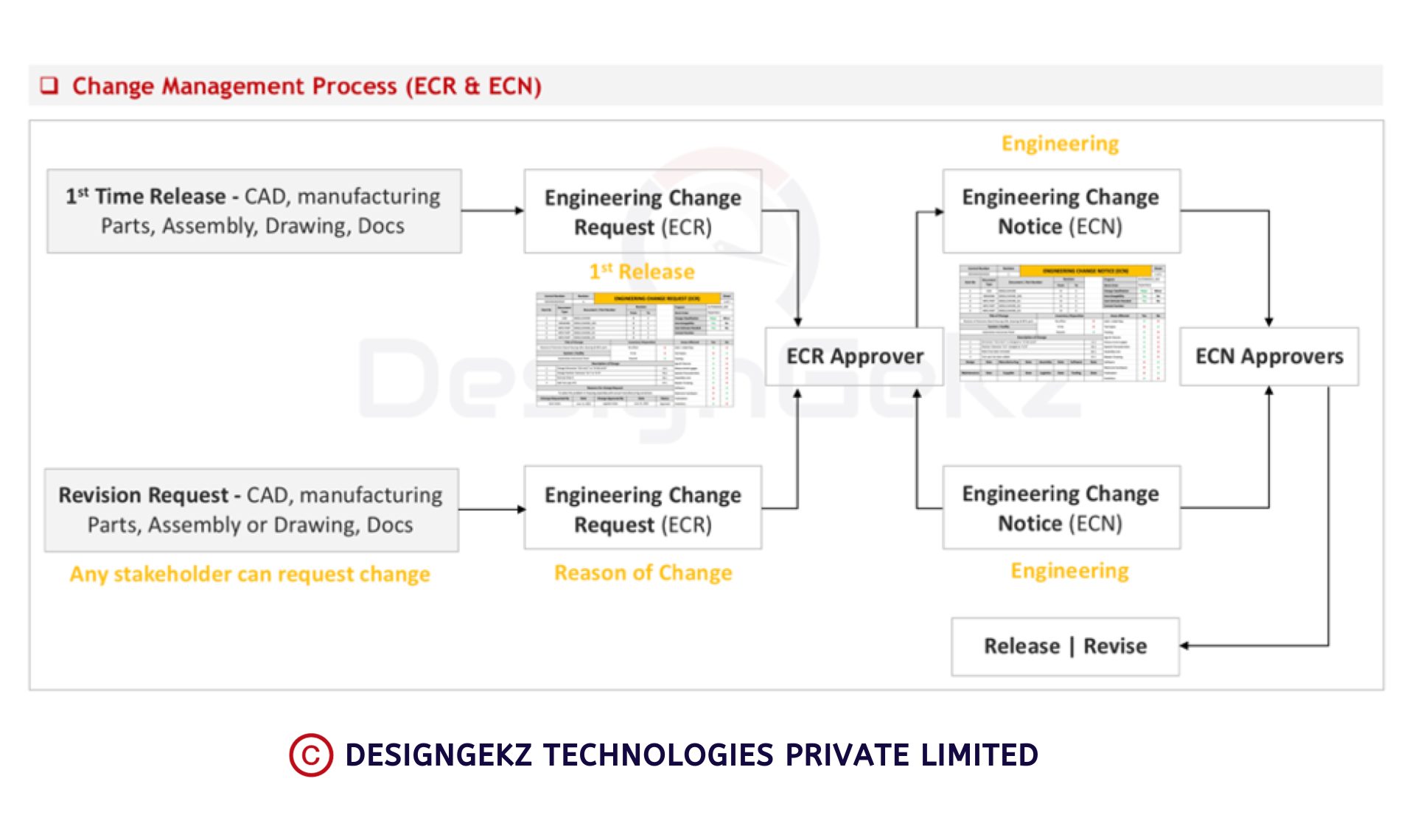

➲ In depth knowledge of these domains helps design engineers to minimize the rework and save the cost for the company. In other words, it’s almost impossible to Design for Manufacturing (DFM) without learning the manufacturing domains.

➲ In depth knowledge of manufacturing domains can add lot of weightage to your resume creating better career growth.

➲ Another great aspect about learning manufacturing domains is that the knowledge is needed for all industries irrespective of their products.

___________________________________________________

⏩ Read my other blogs to understand top mechanical design skills for 10X career growth.

⏩ Read blog: https://designgekz.com/most-in-demand-skills-in-mechanical-design-engineering/

__________________________________________________

⏩ For career planning or enquiring about the courses, write to us at kevinkutto@designgekz.com or call us @ +91-8329029492 | 9881521371

__________________________________________________

⏩ Learn most in demand mechanical design skills like Plastic | Sheetmetal domains, NPD | NPI Process, DFMEA, GD&T (Basic & Pro), PPAP, Tolerance Stackup Analysis, Value Engineering and more with our Signature mentorship Program – Master Diploma in Plastic & Sheetmetal Design Professional (PSDP):

⏩ Read more – https://designgekz.com/course/plastic-sheetmetal-design-professional-psdp/

__________________________________________________

© DesignGekz Technologies Private Limited

__________________________________________________