➲ Your success in mechanical design engineering is the result of your investment into most in demand mechanical design skills.

➲ If you are mechanical engineer the aspiration to become a successful mechanical design engineer or if you are already working in design or cad domains, and want to transform your career to the next level, read this blog till end.

____________________________________________

Author – KEVIN KUTTO

____________________________________________

⏩ Let’s begin this Blog by understanding 2 of the typical top roles in mechanical design.

⏩ The 1st basic role is CAD Engineer or CAD Draftsman.

This is a cad tool specific role in which, in depth cad execution knowledge is mandatory.

Generally, CAD engineers work under the supervision of Mechanical Design Engineers in order to build cad models and drafting of the engineering drawings.

⏩ The 2nd role is Mechanical Design Engineer.

➲ This role is all about designing a product which could work as intended. In other words, it’s all about transforming vague VOC into the tangible, functional product which meets all product requirements.

➲ Mechanical Design Engineer’s role is more versatile and challenging role because it’s not easy at all to make product work and still meeting hundreds of design specifications as per customer’s needs and government agency needs.

➲ And that’s why I have put down this video to bring your attention to the top 10 knowledge and skills for mechanical design engineers which have potential to transform your career to the next level.

➲ Interestingly, these skills are required in design irrespective of product or industry.

➲ It’s sad to see so many engineers are struggling in their career even after spending tons of money in learning cad skills. This video could save lot of headache for you.

____________________________________________

⏩ Most in demand Mechanical Design Skills:

⏩ Mechanical Engineering Skills:

➲ In order to design a a functionally working product which sustain all loading conditions, you must have mechanical engineering knowledge from the subjects like Physics, Strength of Materials, Theory of Machines, Machine Design, Thermodynamics, Fluid Mechanics, Solid Mechanics, Metrology, Material Science, Manufacturing Engineering etc.

➲ Engineering calculations are foundation of any mechanical design to ensure safe and sustainable product under all working and abuse loading conditions.

____________________________________________

⏩ Manufacturing & Product Domain Expertise:

➲ Manufacturing domain knowledge helps design engineers, to deliver a design which could be manufactured in mass production without any defects and could be easily assembled with minimum cycle time.

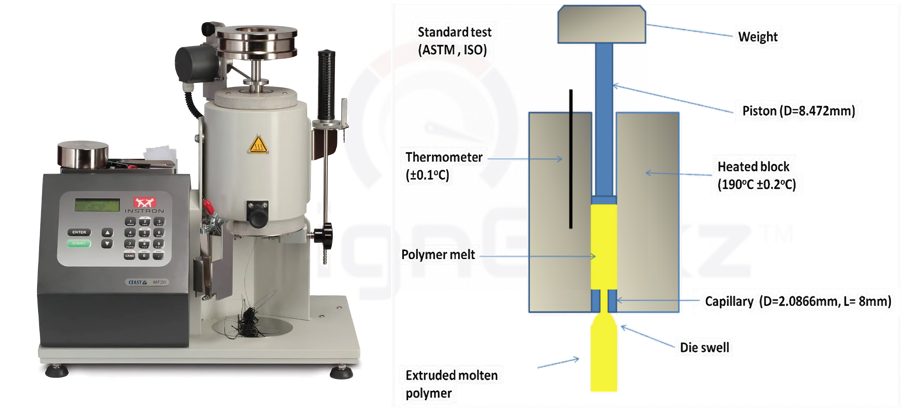

➲ Each manufacturing domain such as Plastics, Sheet metals, Casting, Forging, Machining or 3D printing offers unique manufacturing processes, materials, design best practices, joining methods, tooling challenges, post processing methods, defects & mitigations and their analysis for manufacturability.

➲ I always suggest to learn as many manufacturing domains as possible because any given product will have all kind of parts.

➲ The safe bet is to start with Plastics & Sheetmetal domains as most of the components in automobile, home appliances, aerospace and furniture industries are made up of plastics or sheet metals. Also, these 2 domains are bit complex in terms of manufacturing, tooling and materials. So, engineers with this knowledge are in great demand within the design industry.

➲ But, according to me, one should learn other manufacturing domains as well as your career progresses because any given product will have all sorts of parts.

➲ Apart from manufacturing domains, engineers can also opt for tool design or fixture design domains as well as an alternative path.

➲ Please note that if you want to enter into Product Design career, you need not learn tool, gages or fixture design domains.

➲ So, if any institute is offering you package of plastic & sheet metal domains with fixture or tool design domains, now you know that it’s a waste of time and money.

➲ Product domain knowledge like Car Interiors or exteriors, engines, transmission, home appliances could be complementary knowledge to your manufacturing domain knowledge based upon your area of interest.

➲ But in the initial phase of your career, do not bind yourself with products. If you learn plastics and sheetmetal, you can work in any industry where plastic and sheetmetal knowledge is needed, irrespective of products. Got my point?

____________________________________________

⏩ NPD or NPI process:

➲ This process covers step by step how vague VOC is transformed into tangible & functional product to meet customer and legal requirements.

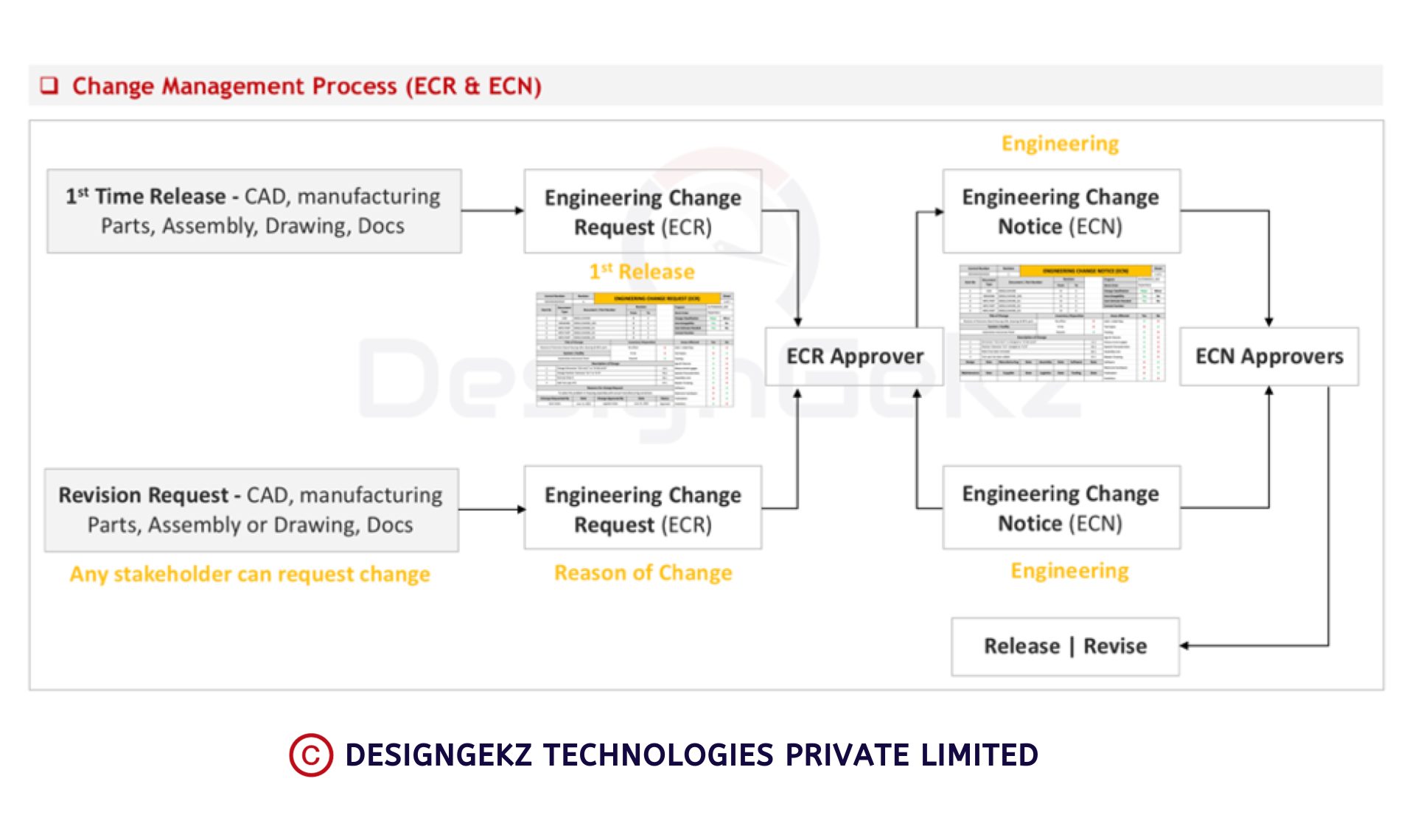

➲ NPD process involves hundreds of tools, techniques, methodologies, deliverables, documents, records, project management tools and inputs which are connected with each other. Until, you understand this connect, you can’t deliver a functional product.

➲ I have created a brief video, just to explain overall steps of NPD process. You can watch it as well.

____________________________________________

⏩ Design for Variation:

➲ This skill helps you to finalise dimensional scheme on the drawing, finalise tolerances for dimensions and geometric controls, optimise the tolerances and dimensions to meet the function and minimise the cost of manufacturing.

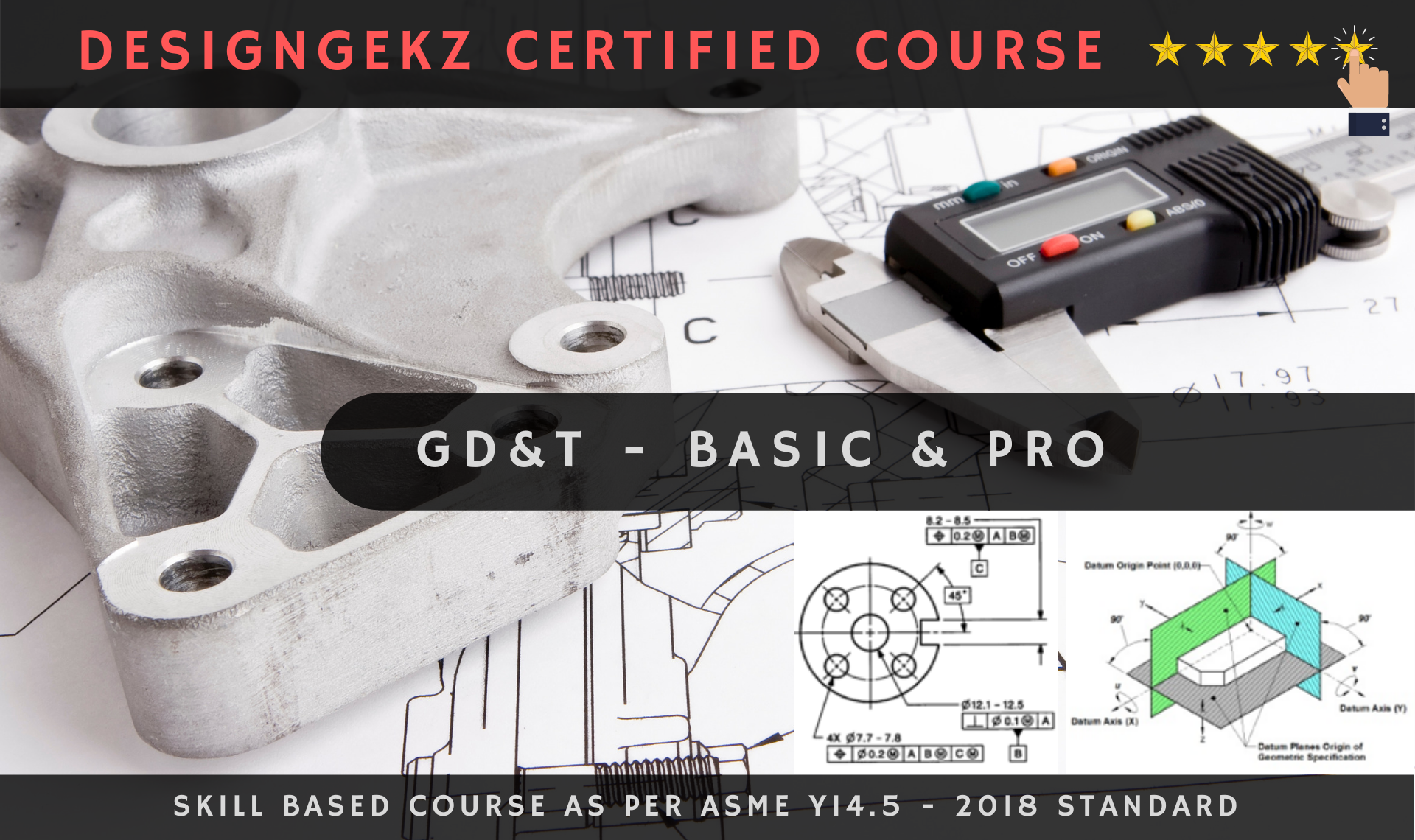

➲ You should focus on learning GD&T as per ASME or ISO standards, general tolerances as per ISO standard, engineering Fits, Tolerance stackup analysis, Manufacturing process capability calculations and how we could identify critical dimensions in the engineering drawing as per function.

➲ If you don’t have this skill, you can’t deliver optimised design.

____________________________________________

⏩ Innovation Mindset:

➲ Innovation is a systematic process and it has many methods which we could leverage.

➲ Engineers with the knowledge of innovations tools, concurrent engineering, design thinking can deliver potential design concepts to meet product functions.

➲ Knowledge of how to select the best concept out of total lot is also crucial.

____________________________________________

⏩ DFMEA & DVP:

➲ This is a very powerful skill in terms of analyzing how functions of the product could fail, their impact on customers and legal requirements, possible root cause, design mitigations and testing for detection.

➲ Out of DFMEA, we also get Design Verification Plan or Test Plan for Product validation.

➲ There 3 main standards which are widely used for DFMEA – AIAG, VDA & AIAG VDA.

____________________________________________

⏩ Systematic problem Solving:

➲ It consists of PDCA & LAMDA approaches, Root cause analysis methods, systematic problem-solving methods like 8D & A3 and also Containment | Corrective | Preventive actions.

➲ Without these skills, engineers can’t solve the design problems.

____________________________________________

⏩ Design for X:

➲ Design for x includes for Manufacturing, Assembly, Reliability, Serviceability, Loads, Sustainability, Modularity and dozens of other factors.

➲ If you know how to design for X, you can deliver functional designs with confidence.

____________________________________________

⏩ Value Analysis & Value Engineering (VAVE):

➲ The Value Engineering & Value Analysis is a methodology to increase value of the product by optimizing functions with the minimum cost.

➲ Knowledge of Value Engineering helps design engineers to deliver great Product value for the customers.

____________________________________________

⏩ Production Part Approval Process (PPAP):

➲ Production Part approval or PPAP includes 18 documents and records as per IATF 16949 standard. Design engineers have to play active role in terms of preparing those documents or records as well as their approval.

➲ So, PPAP knowledge is very important for design engineers.

____________________________________________

⏩ CAD Software Expertise:

➲ Unfortunately, most of the engineers are misguided to waste their time and money in learning multiple cad and simulation tools.

➲ CAD tools like Catia, Creo, UG NX, Solidworks are very popular in design industries.

➲ My suggestion for fresher level is to focus on only 2 CAD software but learn them in great details.

➲ If you want to work in automobile, Catia + Creo or UG NX could work well.

➲ If you want to work in home appliance, Creo + Solidworks could work well.

➲ In aerospace industry, Catia + UG NX or Creo could work well.

➲ Learning simulations software is total waste of time, for design role because you will never get chance to use it. Simulations engineers do simulations.

➲ So, choose to learn cad software based upon your interest of domain.

____________________________________________

⏩ Soft Skills:

➲ Apart from these technical skills, one also need to master soft skills like leadership skills, communication skills, presentation skills, negotiation, Conflict Management, Project Management and interview skills.

____________________________________________

⏩ Read my other blogs to understand roles and responsibilities of CAD Engineer, Mechanical Design Engineer & Product Designer.

__________________________________________________

⏩ For career planning or enquiring about the courses, write to us at kevinkutto@designgekz.com or call us @ +91-8329029492 | 9881521371

__________________________________________________

⏩ Learn most in demand mechanical design skills like Plastic | Sheetmetal domains, NPD | NPI Process, DFMEA, GD&T (Basic & Pro), PPAP, Tolerance Stackup Analysis, Value Engineering and more with our Signature mentorship Program – Master Diploma in Plastic & Sheetmetal Design Professional (PSDP):

⏩ Read more: https://designgekz.com/course/plastic-sheetmetal-design-professional-psdp/

__________________________________________________

© DesignGekz Technologies Private Limited

__________________________________________________