➲ Plastic Design Domain is one of the most popular career option for Mechanical Design Engineers considering it’s wide application in automotive, home appliances, medical & aerospace industries.

➲ The purpose of this blog is to educate aspiring mechanical design engineers about the importance of Plastic Domain knowledge in overall product design projects.

______________________________________________

⏩ Author – JAGADISH ATOLE

______________________________________________

⏩ Plastic Design Domain:

➲ Plastics are the key materials at the heart of many industries including automobile, aerospace, home appliance, consumer durables, medical equipments and many more.

➲ We can conveniently say that we are living in the era of plastics.

➲ We use plastics in the numerous products which we use in day to day lives such as toothbrush, cloths, wearables, shoes, electronic gadgets, luggage carriers, home appliances, furniture, computers, laptops, watches, kitchen utensils and appliances, medical equipments, automobile parts such as bumpers, mirrors, dashboards, seating system parts, door trims, center consoles, overhead parts, lighting system, climate control unit, steering system and Instrument panel, fenders, wipers & more.

➲ In automobile sector, more and more sheet metal parts like bumpers, fenders are being converted into plastic parts to enhance aesthetics and better weight to strength ratio which is critical aspect in terms of Electrical Vehicle Performance now days.

➲ Plastic allows relatively complex and aesthetically appealing geometries, colors, textures, metallic overmolding.

➲ Now a days, plastics is the better and economical alternative for the wood furniture like chair, table, kitchen cabinets, cupboards, etc.

➲ The furniture made with plastic is more durable and light weight than the wood furniture and it respect the environment by saving the trees.

➲ Plastics is becoming increasingly popular in medical industry as well. We can implant the organs or parts made with plastic in the human body as some biocompatible plastics can be human implantable. The products like syringes, IV bottles, testing devices, specimen collection bottles, catheters, dialysis units, saline tubes are made with plastics and the testing or checking equipments like MRI, CT scan, X-ray, sonography etc. are also made with plastics where metal is not allowed.

➲ From all these examples we can conclude that plastic has its applications in almost every industry and we can’t eliminate the plastic from our life.

______________________________________________

⏩ Top 5 reasons of the popularity of Plastics:

➲ Light weight than most of the metallic products – It is the most important winning point for plastic that is light weight and sufficient strength.

➲ High flexibility – It helps to make flexible products which defrost and regains its shapes rather than attaining permanent deformation as in case of metallic products.

➲ Ease of manufacturing – With the moulding process we can create the part with any shape from simple to complex or of intricate geometry with super finish which reduces the needs of post processing operations or after moulding operations to a minimum and therefore reducing the manufacturing cost.

➲ Ease of assembly and maintenance – We can design the assembly features on the plastic parts according to its function and applications. Plastics feature requires less assembly time compared to metallic parts and as plastic feature provides flexibility, so it can be used for multiple cycle of operation during assembly and disassembly for service and maintenance purpose.

➲ Plastics availability – Plastics are available in wide range of technical grades, colors, textures. It helps to make multipurpose plastic products & customize the plastic as per requirements.

______________________________________________

➲ Mechanical Design Engineers with Plastic domain knowledge could get tons of opportunities in automobile, home appliance, aerospace and medical industries.

______________________________________________

⏩ Design Engineers needs to learn following aspects in Plastic domain:

➲ Material Selection

➲ Plastic Process selection

➲ Understand tooling aspects

➲ Apply Best practices to design plastic features

➲ Plastics joining processes

➲ Plastic machining & post processing

➲ CAD best practices to design plastic parts

➲ Moldflow analysis aspects, DFM & DFA

➲ Plastic structural Design

______________________________________________

➲ Design engineers with great understanding & application ability of Plastic domain are in high demand across design industries.

___________________________________________________

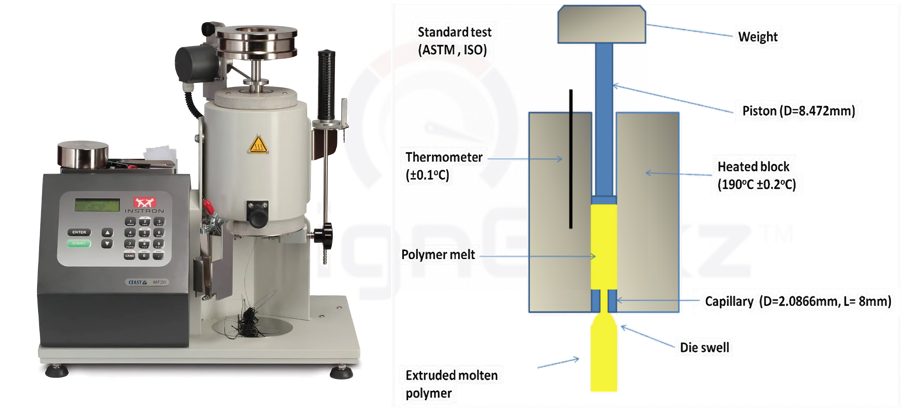

⏩ Read my other blogs to understand Melt Flow Index (MFI) for Polymers

⏩ Read blog: https://designgekz.com/melt-flow-index-mfi-of-polymers/

__________________________________________________

⏩ For career planning or enquiring about the courses, write to us at kevinkutto@designgekz.com or call us @ +91-8329029492 | 9881521371

__________________________________________________

⏩ Learn most in demand mechanical design skills like Plastic | Sheetmetal domains, NPD | NPI Process, DFMEA, GD&T (Basic & Pro), PPAP, Tolerance Stackup Analysis, Value Engineering and more with our Signature mentorship Program – Master Diploma in Plastic & Sheetmetal Design Professional (PSDP):

⏩ Read more – https://designgekz.com/course/plastic-sheetmetal-design-professional-psdp/

__________________________________________________

© DesignGekz Technologies Private Limited

__________________________________________________