➲ Change Management Process (CMP) is an effective way to manage changes in the design of product and engineering documents such as engineering drawings, cad files or requirement spec documents.

________________________________________

Author – KEVIN KUTTO

________________________________________

➲ Changes in any design are very common and are driven by many reasons such as change in customer requirements, change in government laws, to address field or internal product failures or quality issues, changes driven by value analysis etc.

➲ Biggest challenge in driving design changes in the product is to ensure that all the product stakeholders like manufacturing, quality, vendors, process planning, development, testing, tool makers, gage makers, jigs and fixture makers etc understand the changes simultaneously and exactly in a same way as intended.

➲ Imagine the kind of chaotic situation, if manufacturing and quality engineers have different versions of engineering drawings. And that’s the reason why, managing changes, once designs are released is so crucial.

➲ The process to manage and control product design changes is popularly known as “Change Management Process (CMP)”

________________________________________

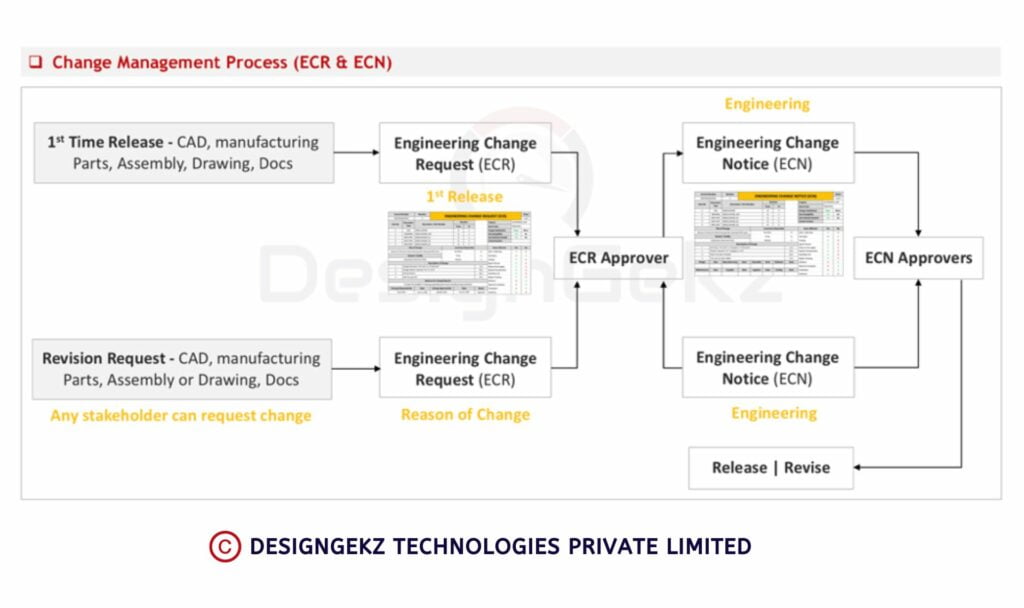

⏩ Typical steps in Change Management Process:

Step 1 – Engineering Change Request (ECR):

➲ This step answers “What changes do we need in design and Why do we need them?”

➲ Each ECR has unique Tracking Number and could list one or many changes in one or many pats or assemblies of the product.

➲ This steps provides supporting data, test results, simulation reports or cost data to convince an ECR Approver why these changes make sense.

➲ This step also lists impact of change and cost implications of change.

➲ ECR is generally analysed & approved by ECR Approver (Engineering Manager or Subject Matter Expert)

➲ ECR Approver can take help of concerned departments if he needs more supporting data to take decision on ECR.

➲ ECR Approver can Approve | Reject | Recycle (Ask for more info) the ECR with reasons.

________________________________________

Step 2 – Engineering Change Notice (ECN)

➲ ECN is always followed after ECR is approved by an Approver.

➲ Single ECN could list all the changes approved in ECR or we can also create multiple ECN’s by splitting the changes approved by ECR.

➲ Each ECN has to be associated with an Approved ECR.

➲ Engineering department implements all the changes approved by ECR and promotes the engineering document to the next revision.

➲ Engineering drawings also mention unique ECN Tracking number.

➲ ECN includes “associated ECR tracking number, what and where we have implemented changes in the engineering drawing, impact of changes, disposition of inventory, list of stakeholders who need to know the changes and their signatures (physical or digital), associated products or models and manufacturing parts or assemblies”

➲ When each stakeholder signs and approves the change, admin promotes the ECN as “Approved” and that means design change has been released or revised.

➲ It also means that each stakeholder now must use latest engineering information to manufacture the parts or assemblies.

➲ So, Engineering Change Request (ECR) and Engineering Change Notice (ECN) as part of “Change Management Process” are effective steps in managing design changes effectively.

________________________________________

⏩ Read my other blogs to understand top mechanical design skills for 10X career growth.

⏩ Read blog: https://designgekz.com/most-in-demand-skills-in-mechanical-design-engineering/

__________________________________________________

⏩ For career planning or enquiring about the courses, write to us at kevinkutto@designgekz.com or call us @ +91-8329029492 | 9881521371

__________________________________________________

⏩ Learn most in demand mechanical design skills like Plastic | Sheetmetal domains, NPD | NPI Process, DFMEA, GD&T (Basic & Pro), PPAP, Tolerance Stackup Analysis, Value Engineering and more with our Signature mentorship Program – Master Diploma in Plastic & Sheetmetal Design Professional (PSDP):

⏩ Read more – https://designgekz.com/course/plastic-sheetmetal-design-professional-psdp/

__________________________________________________

© DesignGekz Technologies Private Limited

__________________________________________________