➲ Transforming vague customer needs into a functionally working product can be very challenging task.

➲ Many times you might have an idea around customer need in a particular market, but you are not sure how to bring the product to that market.

➲ Thankfully, we have got a blueprint in the form of new product development process in order to bring your idea into a functionally working product.

________________________________________________

⏩ Author – KEVIN KUTTO

________________________________________________

⏩ Introduction to New Product Development Process (NPD | NPI Process):

➲ New Product Development Process refers to the step by step process that goes into bringing a new product to the market, starting from brainstorming an idea, understanding its market fit, detailing the design of the product, prototyping and finally commercialising it.

➲ Product Design is the process to transform customer’s needs into tangible & functionally working product or designing features which will address your target customer’s pain areas (problems), reduce their work efforts or improve their work efficiency.

➲ For any company, predictability of the design outcomes is the key to success of the project, as many stakeholders like end customers, shareholders, dealers, suppliers as well as government would be eagerly looking at the company to meet it’s commitment to deliver the functional design on time, on cost & on quality.

➲ Achieving this predictability is possible only if company’s new product development process is predictable as much as possible and facilitates reduced risk to the project execution. And, that’s where New Product development process (NPD | NPI process) helps the companies to a great extent.

➲ New Product Development Process (NPD) or New Product Initiation Process (NPI) is a step by step process used by companies to transform customer requirement into functionally working product.

________________________________________________

⏩ New Product Development (NPD I NPI) process involves following steps:

1️⃣ Market Opportunity Exploration & Target Setting

2️⃣ Concept Exploration & Selection

3️⃣ Detail system design & Concept Feasibility

4️⃣ Design Release

5️⃣ Process & Tool Design

6️⃣ Product Approval (Process & Product Validation) & SOP

7️⃣ Lessons Learned (Feedback Assessment)

________________________________________________

➲ Each of this step includes many tool & techniques, methodologies which enable the companies to meet the criteria of each of the phase.

➲ Companies generally tailor out this process as per their product needs, but overall intent and steps remain almost similar all across automotive, home appliance, medical & other industries.

➲ Since Mechanical Design Engineers design the products and play critical role in every phase of New Product development process (NPD | NPI process), the knowledge or overall NPD | NPI process adds lot of weightage in your resume.

➲ Also, NPD | NPI knowledge helps you to understand all the deliverables of the overall design project and their interlinks with each other and that’s why it adds lot of advantage to your design career as you move up the ladder in Design Lead roles.

________________________________________________

Now that we understand, an importance of new product development process, let’s understand intent of its each step.

1️⃣ Market Opportunity Exploration & Target Setting:

➲ In this step of new product development process, we conduct market research and competitor analysis to understand current market sentiments, technology trends and gaps in the market to finally arrive to customer needs.

➲ In this phase, we also transform vague Voice of customer (VOC) into measurable, technical specs which help us to design the product.

➲ Technical targets might evolve further as per customer feedback and brainstormed ideas.

________________________________________________

2️⃣ Concept Exploration & Selection

➲ In this step of new product development process, we brainstorm ideas and develop preliminary concepts to meet technical specs, aesthetic and craftsmanship needs, safety and regulatory compliance of the product.

➲ We conduct preliminary evaluation of potential concepts with the help simulation, calculations, prototype evaluations and cost analysis to drill down into one or two potential concepts.

➲ We use tools like Pugh Matrix to select the final concept among few potential options.

________________________________________________

3️⃣ Detail system design & Concept Feasibility:

➲ In this step of new product development process, we detail out the selected potential concept upto the level to release for tooling and production.

➲ This is the step of NPD process where we design engineers spend our most of the time in multiple iterations of the design until we get the design right to meet all customers needs defined in the 1st step.

➲ We design for manufacturing and assembly, safety, reliability, sustainability, cost, servicing, regulatory compliances, manufacturing variations, packaging and shipping, modularity, craftsmanship and aesthetics, sustaining of physical and thermal loads and cost.

➲ In short, this step is bit complex and has lot of trade offs as it involves finalising of almost all the aspects of design to meet customer targets set the 1st step.

➲ We involve all our critical stakeholders like manufacturing, assembly, tool makers, fixture makers, safety engineers, reliability engineers early on in this step to take their feedbacks and update our design to avoid late design changes.

➲ This is also called as concurrent engineering where work progresses collectively.

➲ Outcome of this step if your final design (cad, engineering drawings, BOM) ready to release.

________________________________________________

4️⃣ Design Release:

➲ In this step of new product development, we release our design (cad, engineering drawings, BOM) to all our stakeholders.

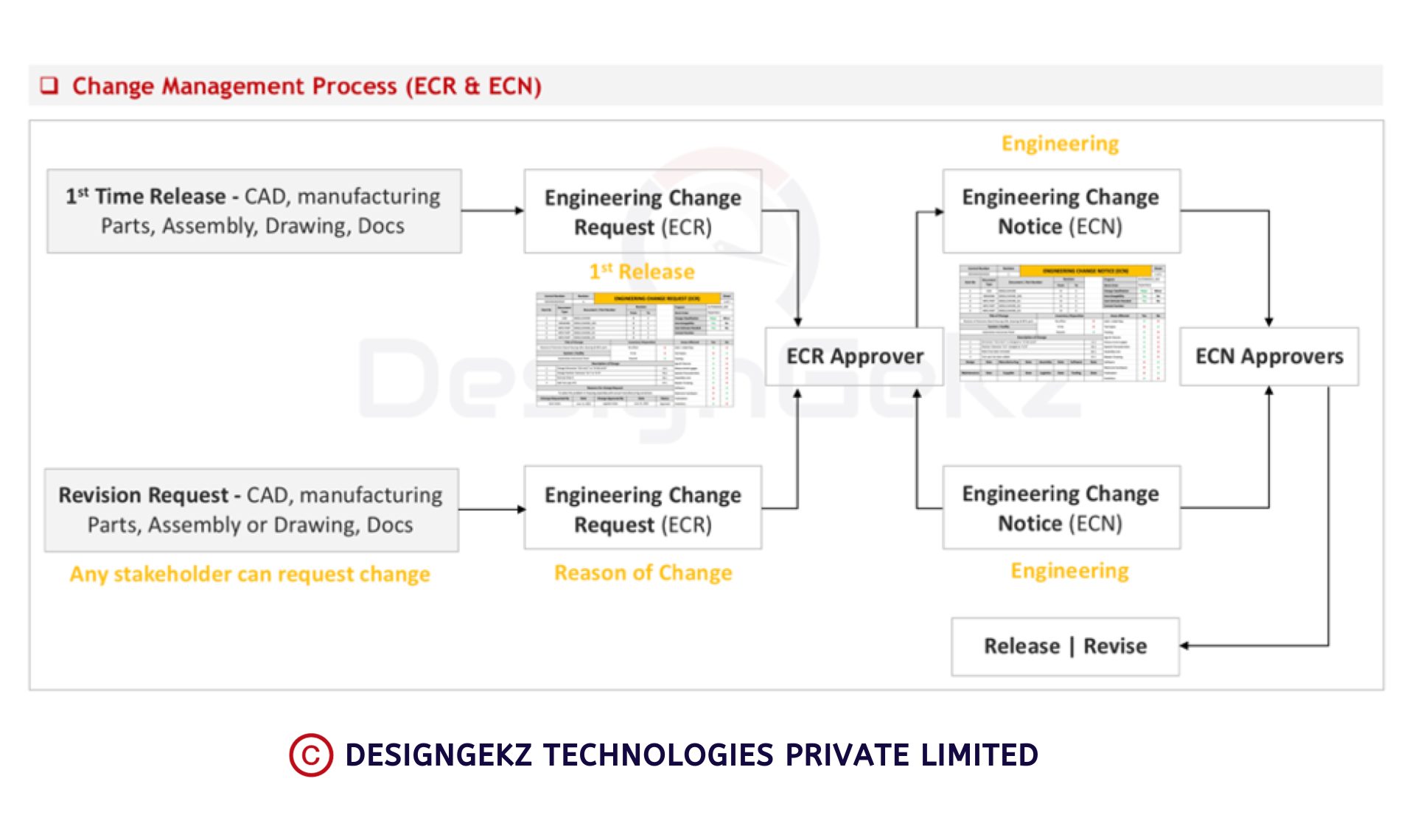

➲ Any further changes in the design has to be done through “Change Management Process”.

➲ I have written separate blog to explain this process. You can read it as well.

Read the blog: https://designgekz.com/change-management-process-ecr-ecn/

________________________________________________

5️⃣ Process & Tool Design:

➲ In this step of new product development process, all stakeholders including development, process planning, tool makers, jig and fixture makers, gage makers, suppliers, labs, manufacturing, assembly begin their execution work.

➲ At the end of this step, we get tooled up parts ready for Pilot build in order to validate the manufacturing process and product.

➲ This is also the step where 1st parts out of tools and tools are approved for production.

________________________________________________

6️⃣ Product Approval (Process & Product Validation) & SOP:

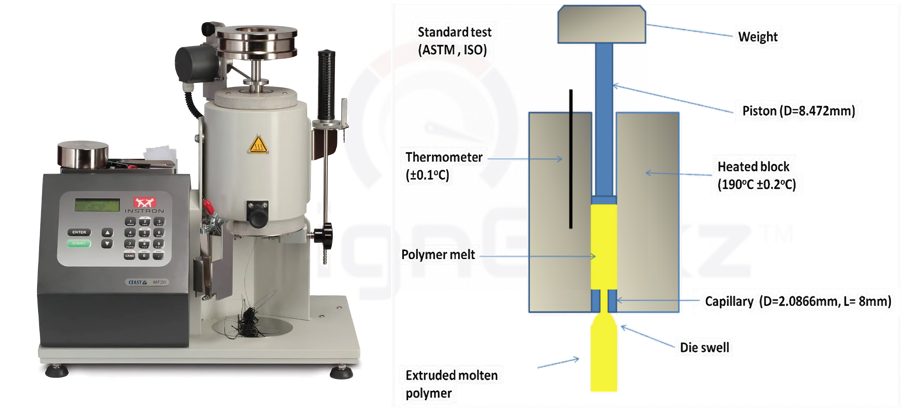

➲ In this step of new product development process, we assemble the parts coming out of final tools and manufacturing line, assemble them on final assemble lines, with final workers, cycle time, measure them with final gages. We do that to add all possible manufacturing and assembly variations into the product and then we finally test these products in the agency approved labs.

➲Once product passes all the tests, product is approved and we can proceed to production.

➲ SOP or start of production, also includes handover of production line from Development Engineers to manufacturing and assembly team.

________________________________________________

7️⃣ Lessons Learned (Feedback Assessment):

➲ Even though this step is the last step in NPD process, actually feedback assessment and correction is a continuous process throughout the product design and development.

➲ Lessons learned are very critical knowledge for future projects to avoid similar mistakes.

So, hopefully, by this time, you must have got a understanding of new product development process or NPD | NPI process.

________________________________________________

⏩ Now, you can learn and master all tools and techniques and methodologies popularly used in New Product Development Process as well as most in demand design skills like DFMEA, Value Engineering, Systematic Problem Solving, GD&T (Basic & Pro), tolerance Stackup Analysis and manufacturing domains like plastic design domain | sheetmetal design domain from highly experienced industry mentors at Designgekz.

⏩ Know more about the course: https://designgekz.com/course/plastic-sheetmetal-design-professional-psdp/

________________________________________________

⏩ For career planning or enquiring about the courses, write to us at kevinkutto@designgekz.com or call us @+91-8329029492 | 9881521371.

________________________________________________

©DesignGekz Technologies Private Limited

________________________________________________