➲ The purpose of this blog is to educate aspiring design engineering about responsibilities of Mechanical design engineer & CAD engineer roles.

➲ This information is very crucial for aspiring Mechanical design engineers before you begin your successful career journey.

_________________________________________________

⏩ Author – KEVIN KUTTO

_________________________________________________

⏩ Job Responsibilities of Product (Industrial) Designers:

➲ They are responsible for aesthetic & craftsmanship requirements of the product such as A Surfaces, flow-lines, textures, colors, gaps & flushness, alignments between components in an assembly.

➲ They drive look of the product in order to trigger five senses [see, smell, taste, feel & hear] of the human beings to promote selling of the product.

➲ They provide A surfaces [3D CAD of A surface quality] & Rendering [2D Styling] to Mechanical Design Engineers. They prepare styling sketches on paper and execute them in styling tools like Rhino, Autodesk Alias, Autodesk Sketch Book Pro, Adobe Photoshop, MODO. They also prepare clay models of the products.

➲ Industrial Designer job role is more suitable for engineers who are very innovative & passionate to put on paper out of box designs.

_________________________________________________

⏩ Job Responsibilities of Mechanical Design Engineers:

➲ Mechanical Design Engineers on other hand, are responsible for designing the functional product which meets all technical requirements of the product which were set in the target setting event of NPD process as well as to meet aesthetic & craftsmanship needs set by Industrial designers along with regulatory requirements.

➲ Mechanical design engineers follow NPD or NPI process. They brainstorm the concepts & select the best concepts using decision making tools.

➲ They design the part for manufacturing & assembly [DFM & DFA]. They are responsible to design the system for safety, reliability, usability, modularity & tolerance variations.

➲ They use GD&T for functional dimensioning & tolerancing and TOL stack up analysis to verify as well as optimize them. They are responsible for meeting BOM cost targets as well as minimize tooling cost by designing the parts in simplest possible way for manufacturing.

➲ They select materials, design for physical & thermal loads. They also take lead to patent the unique concepts in the market.

➲ They are responsible to study failure modes and mitigate them using DFMEA, mitigate technical risks using Risk Management, they are the ones who will study PPAP documents from suppliers and sign off.

➲ They work with simulation team to get structural, thermal & CFD analysis done for load cases and improve design accordingly.

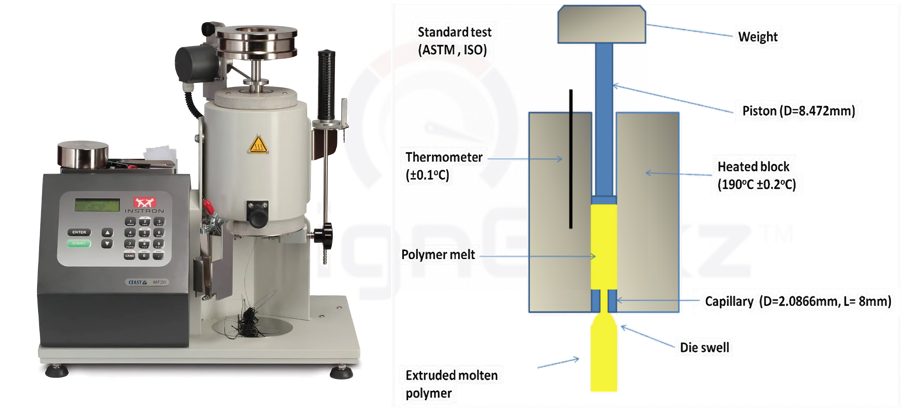

➲ They also work with Moldflow [ Plastics] or Forming [Stamping] analysis teams to ensure that all parts are manufacturable with no defects.

➲ They are responsible to coordinate with all stakeholders like MFG, Quality, Assembly, Safety, Usability, Reliability, Test Lab, Government Approval Agencies, Tool makers, Gage Makers, Jig & Fixture Suppliers, Process Planners, component suppliers to make sure that they all meet design requirements in order to launch the working product successfully in the market on time, on cost & on quality.

So, by this time, you must have realised how much broader role of Mechanical Design Engineer is in NPD process.

_________________________________________________

⏩ Job Responsibilities of CAD Engineer:

➲ CAD Engineer is CAD tool specific role. So that means, CAD engineers must have very good hands over CAD tools like CATIA, CREO, UG NX, SOLIDWORKS etc. whichever is needed by the company.

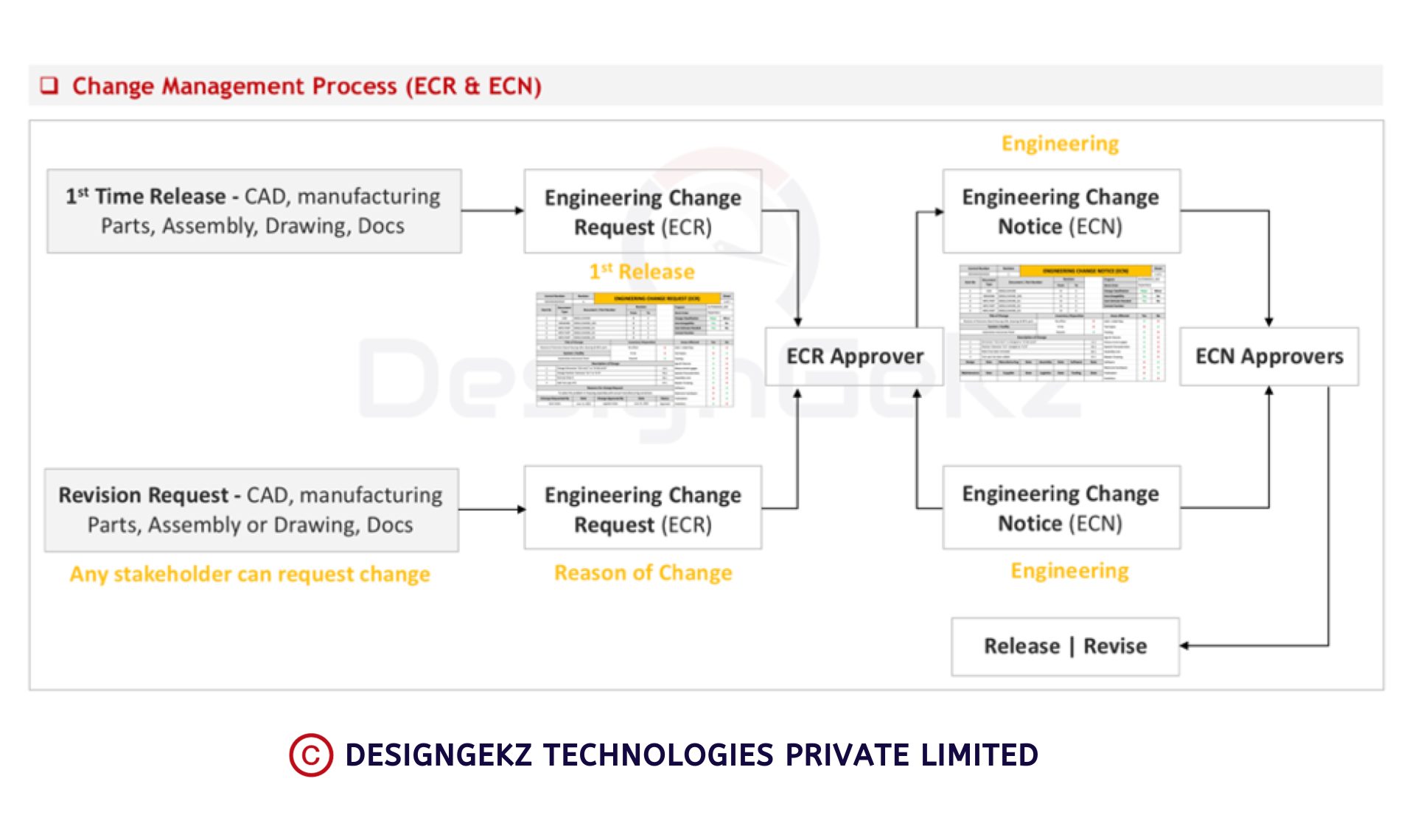

➲ CAD engineers [CAD Draftsman] work under the guidance of Mechanical Design Engineers and they are responsible for preparing 3D CAD models, Engineering Drawings, maintaining Master Assembly and Release / Revision of the CAD or Drawings via ECN process & in PLM platforms like Windchill or Product Center.

➲ Most of the companies hire fresher mechanical engineers as a CAD engineer and eventually you need to grow to Mechanical Design Engineer role.

➲ Unfortunately, now days most the CAD engineers are stuck into CAD roles for years due to lack of knowledge and skills to grow as a Mechanical Design Engineer. Eventually, you end up becoming vulnerable to lose job if you stuck up in CAD roles for too long as engineers with lesser similar experience can easily replace you.

➲ And that’s the exact reason why fresher Mechanical Engineers should build strong foundation of their design career by learning most in demand design domains like Plastic Design or Sheetmetal design and focus on learning core design skills which enable them to perform job duties of Mechanical Design Engineers.

➲ On contrary, fresher engineers are misguided to learn multiple cad & simulation tools which is of no use to become successful mechanical design engineer. You hardly get chance to work on multiple cad tools in any company. Also, as & when needed you can learn any CAD tool.

Hopefully, now you have good clarity to understand the difference between these three roles.

_________________________________________________

⏩ For career planning or enquiring about the courses, write to us at kevinkutto@designgekz.com or call us @ +91-8329029492 | 9881521371

__________________________________________________

⏩ Learn most in demand mechanical design skills like Plastic | Sheetmetal domains, NPD | NPI Process, DFMEA, GD&T (Basic & Pro), PPAP, Tolerance Stackup Analysis, Value Engineering and more with our Signature mentorship Program – Master Diploma in Plastic & Sheetmetal Design Professional (PSDP):

⏩ Read more: https://designgekz.com/course/plastic-sheetmetal-design-professional-psdp/

__________________________________________________

© DesignGekz Technologies Private Limited

__________________________________________________