➲ One can’t become Simulation Engineer by just learning multiple simulation softwares or tools.

➲ Simulation Engineering is expertise job and needs in depth knowledge of mechanical engineering subjects.

_____________________________________________

⏩ Author – KEVIN KUTTO

_____________________________________________

So, what is Simulation Engineer role and it’s responsibilities.

⏩ Job Responsibilities of Simulation Engineers:

➲ Simulation Engineering is highly paid role in design industries.

➲ Many Engineers have misconception that merely learning simulation tools such as ANSYS or HYPERMESH is sufficient to will make them Simulation Engineers which is not true at all.

➲ Simulation tools themselves are not intelligent enough to understand if inputs provided to it are correct or not. It just converts any input provided to it into output and can’t guarantee the accuracy of the output unless inputs are accurate.

➲ That’s the reason why Simulation Engineer’s job is very important. They are the one who analyze in early stage if Product designed by Mechanical Design Engineer will perform intended function or not. That’s the reason why it is very high skill-oriented job.

_____________________________________________

⏩ Requirements to become Simulation Engineer:

➲ Simulation Engineer should have very sound and in-depth Engineering knowledge. Most of the companies recruit Engineers with specialisation like ME, MTECH or PHD for simulation roles.

➲ Most of the training institutes teach students both CAD & simulation tools as a course package.

➲ In my personal view, simulation engineer need not be expert into CAD tools. It’s good to have basic knowledge of CAD but you need to have expertise in simulation software. The simulation engineers must have command over Engineering & mathematics.

_____________________________________________

⏩ Math Modeling

➲ Math modeling is also considered as part of simulation where in tools like Matlab or Simulink enable simulation engineers to build math models around physics behind the working of the product. Math models don’t replace physical testing or other form of simulations, but has ability to provide direction of design in early stages, try multiple iterations of design within very short span of time.

➲ It is a better alternative to hand calculations for sure.

➲ Let’s understand role of simulation engineer with real time demonstration of the role.

_____________________________________________

⏩ Demonstration of Simulation Engineering Role:

➲ Mechanical Design Engineer design a structural plastic part and he wants to select best material for the given application is.

➲ He also wanted to know if his design will sustain structural & thermal cyclic loads.

➲ Also, It’s very crucial for him to understand if designed plastic part will have any molding defects which could affect the performance of the part.

➲ Based upon his Engineering knowledge he has shortlisted few materials whose properties are closer to what is needed.

➲ In such a situation, simulation engineer can play very crucial role.

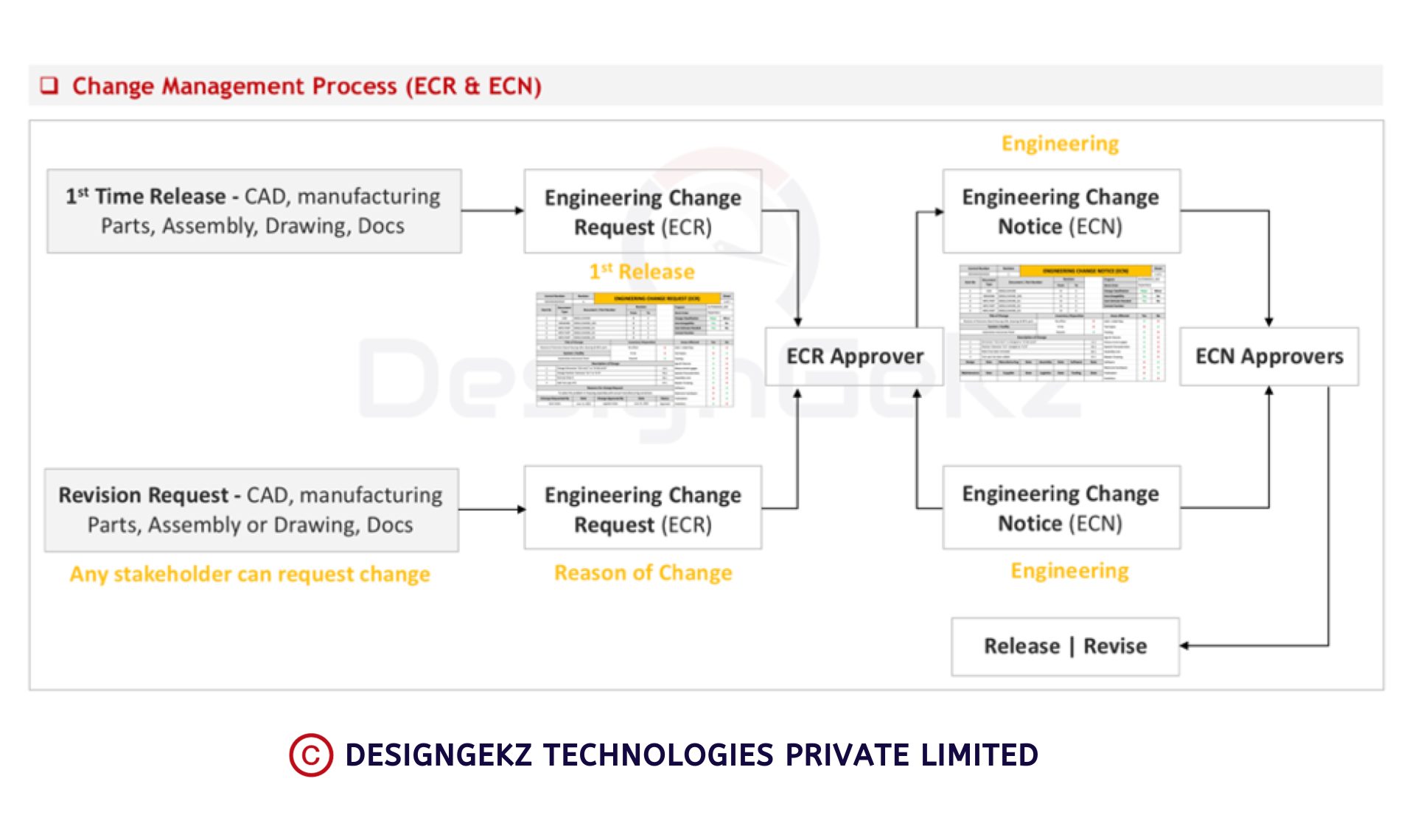

➲ Simulation engineer understands the Design and function of the part from Mechanical design engineer. He also understands boundary conditions, environmental conditions under which the target part needs to work.

➲ Based upon this knowledge & inputs from Mechanical design engineer he builds simulation model with right meshing & boundary conditions using suitable Simulation tool.

➲ He analyses the results to conclude which is the best material option in given situation. He also suggests design improvements to make part structurally robust.

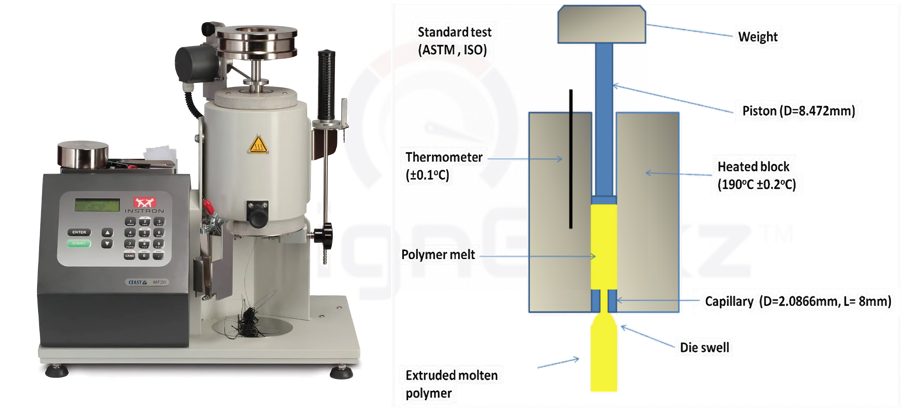

➲ Mold flow simulation engineers use their knowledge of plastic mould design & mold-flow simulation to suggest best gating location, mold pressure etc. in order to minimize plastic defects to ensure that the part is molded as intended by Mechanical Design Engineer.

➲ Simulation engineer also performs “Test to Learn” study in order to build correlation between simulation results and actual test results to build confidence.

➲ Simulations Engineers work closely with Mechanical design engineers to run DOE’s where necessary and optimize the design in early stages itself.

➲ They work to capture knowledge in reusable formats to save future iterations. Simulation is iterative and continual improvement process.

➲ Hope you understand now that simulation role is much more than just application of the simulation software. That’s the exact reason why I said earlier that this job requires very strong engineering knowledge and ability to apply it.

➲ Each simulation tool has unique advantages. Some of the simulation tools such as ANSYS or HYPERMESH are more suitable for structural & thermal analysis while some of them such as MOLDFLOW or THERMOFORM are very useful in checking manufacturing feasibility of plastic or sheet metal parts.

➲ Simulation tools like Tracepro are useful in Light simulations. Matlab and Simulink are very useful in building math models which could play critical role in early design stages.

➲ So, if you are interested in building successful career in simulation, focus more on building engineering capabilities with specialization and learn simulation tools related to your area of interest.

➲ Basic knowledge of CAD tools could help you in saving some time to send CAD data back and forth for small modifications. But those are not the mandatory requirements.

_________________________________________________

⏩ For career planning or enquiring about the courses, write to us at kevinkutto@designgekz.com or call us @ +91-8329029492 | 9881521371

__________________________________________________

⏩ Learn most in demand mechanical design skills like Plastic | Sheetmetal domains, NPD | NPI Process, DFMEA, GD&T (Basic & Pro), PPAP, Tolerance Stackup Analysis, Value Engineering and more with our Signature mentorship Program – Master Diploma in Plastic & Sheetmetal Design Professional (PSDP):

⏩ Read more: https://designgekz.com/course/plastic-sheetmetal-design-professional-psdp/

__________________________________________________

© DesignGekz Technologies Private Limited

__________________________________________________