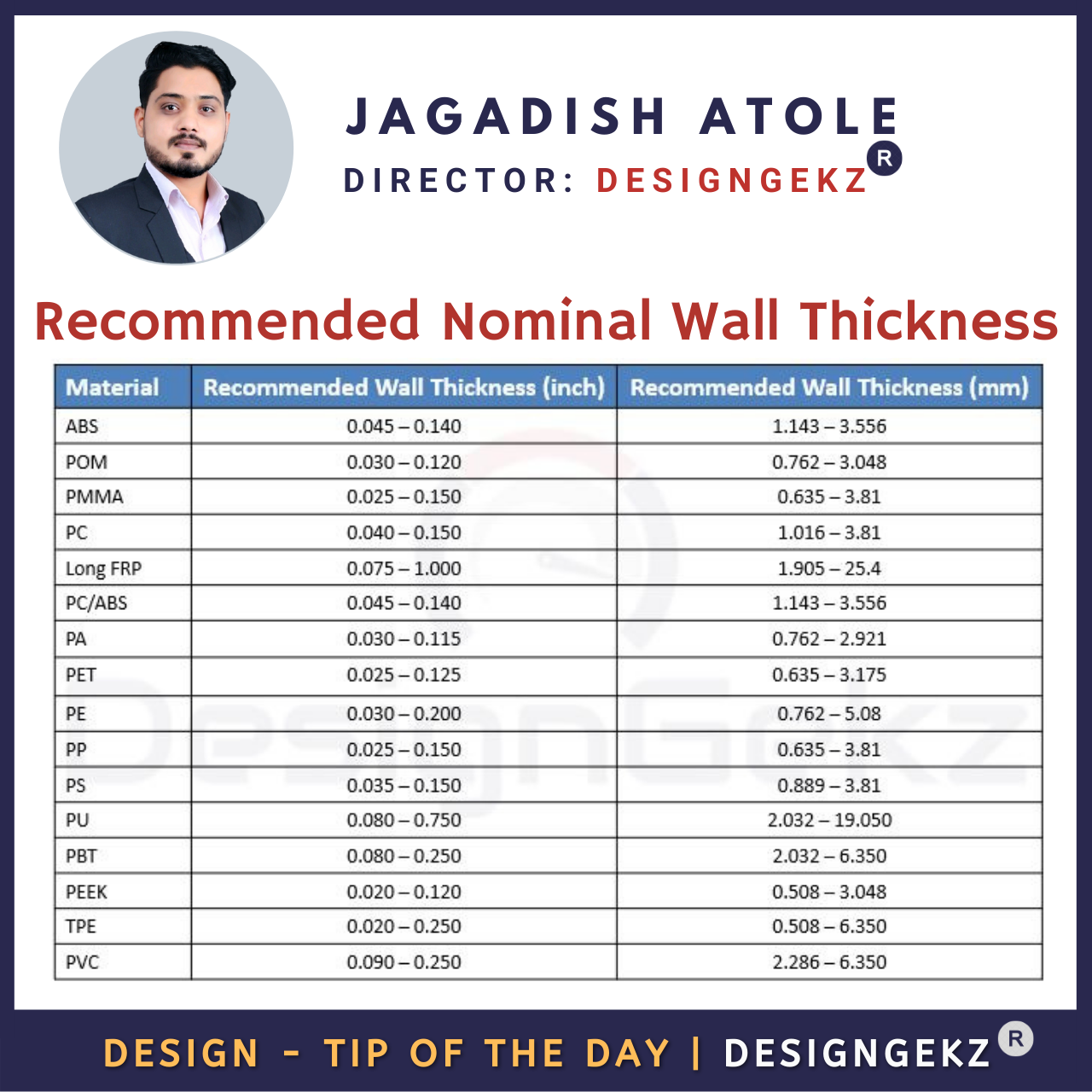

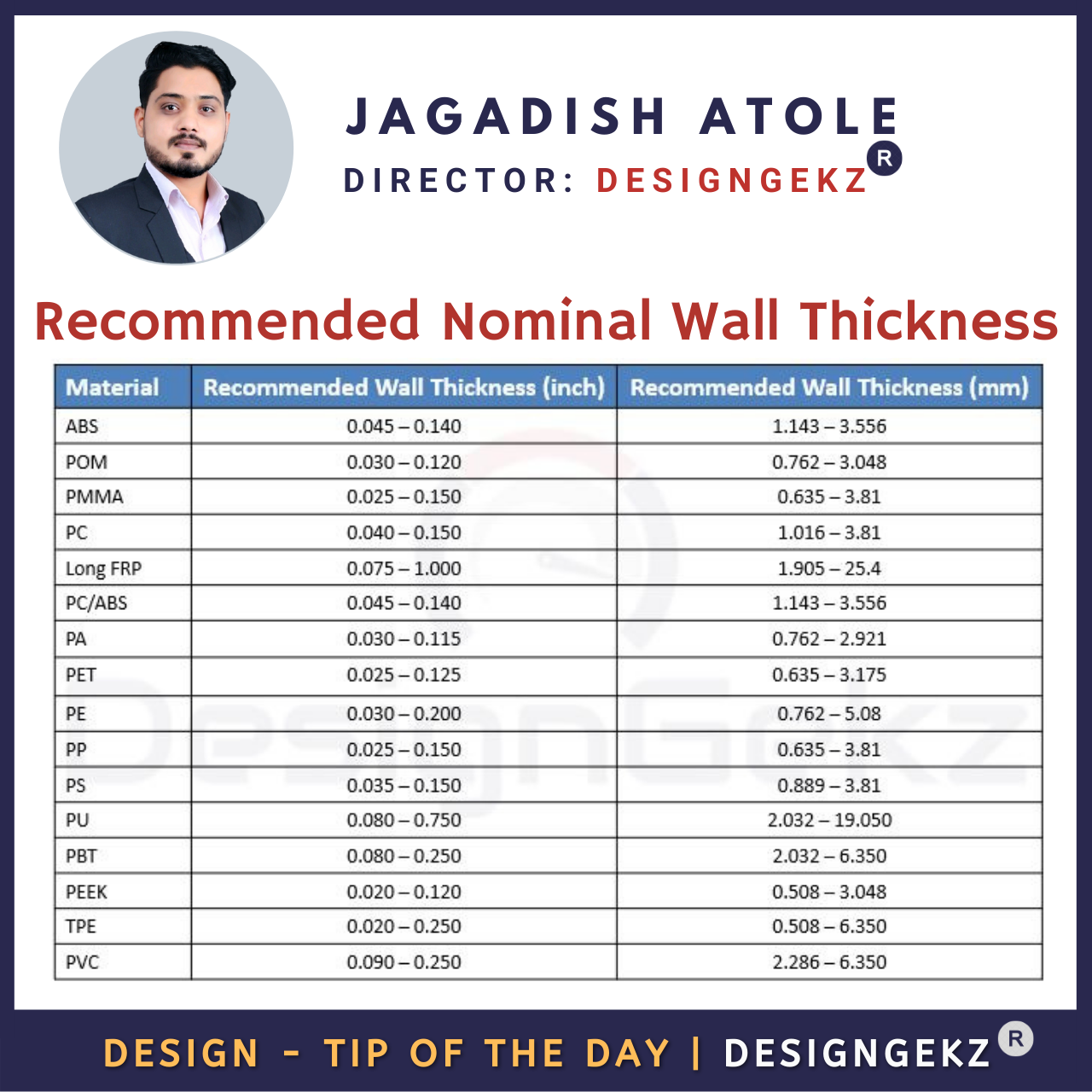

Recommended nominal wall thickness for plastic parts | Jagadish Atole

Recommended plastic part wall thickness 👉 Nominal wall thickness of the part is the major

Recommended plastic part wall thickness 👉 Nominal wall thickness of the part is the major

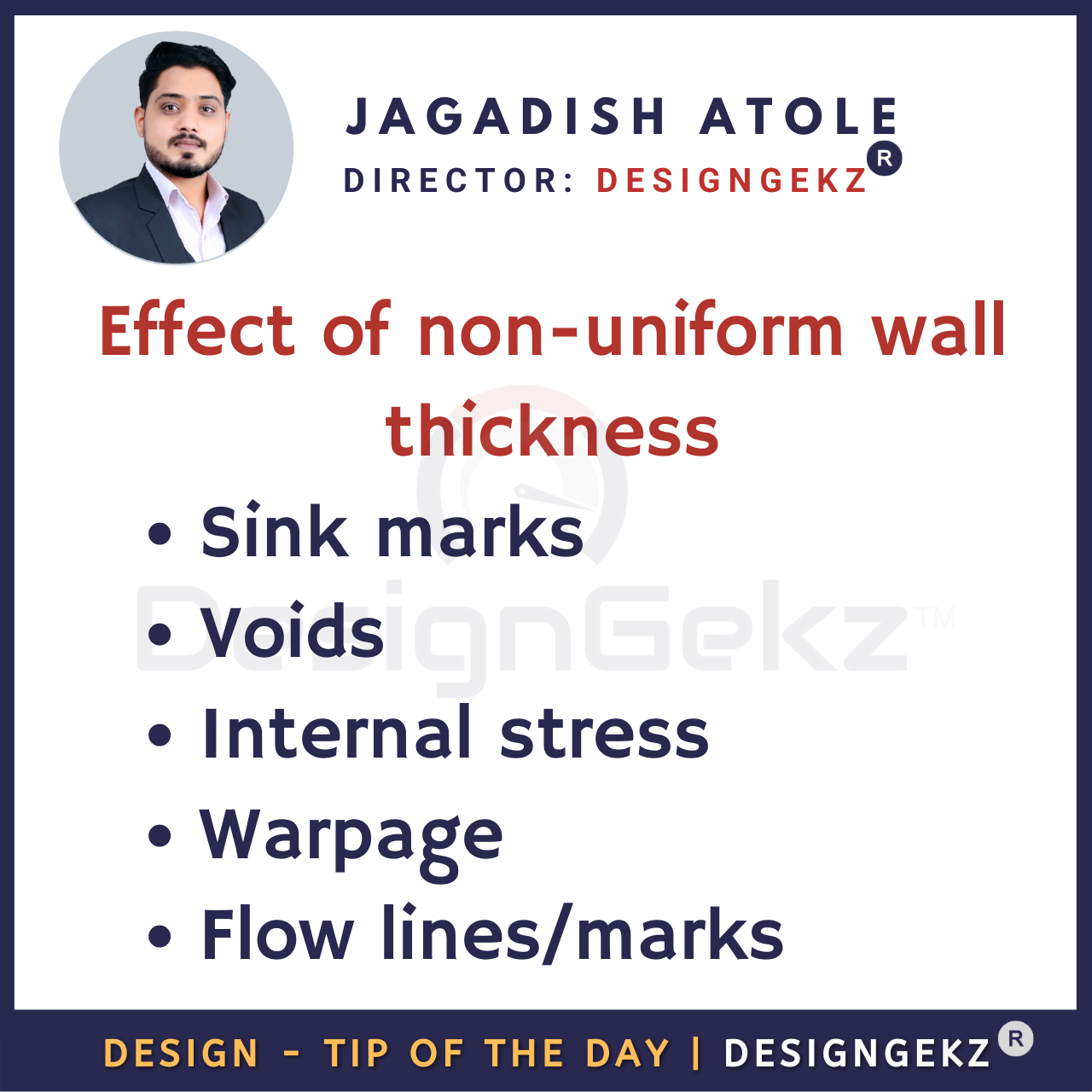

Effect of non-unifrom wall thickness of plastic parts 👉 Sink marks result from a wall

Selection of Nominal Wall Thickness of Plastic Part 👉 Application of the part: – Nominal

Design for Manufacture and Assembly (DFMA) 👉 Design for Manufacture and Assembly (DFMA) is a design approach

Estimation of manufacturing cost 👉 Manufacturing cost estimation is the collection of methodologies and tools

Glass Transition Temperature in Plastics 👉 Glass Transition is a temperature at which an amorphous

K-Factor of Sheetmetal material & it’s significance 👉 K-Factor of sheetmetal is the ratio of

Material Properties – Material Toughness 👉 Material Toughness plays critical role in the applications where

Material Properties – Material Hardness 👉 Material Hardness plays critical role in the applications where

Datum | Datum Feature | Datum Feature Simulator in GD&T 👉 As per ASME Y14.5